The National Robotarium in Edinburgh has launched free workshops to help Scottish businesses assess and prepare for robotics adoption, aiming to boost productivity and competitiveness across the region.

By Naomi Battison, Business Development Executive, National Robotarium

Scotland’s food and drink industry stands at a critical juncture. While robotic technologies are revolutionising working practices globally, many British businesses remain unprepared for this technological shift. The consequences of this unreadiness could prove costly in an increasingly competitive global market.

ABB robot at the National Robotarium (Photo credit: The National Robotarium)

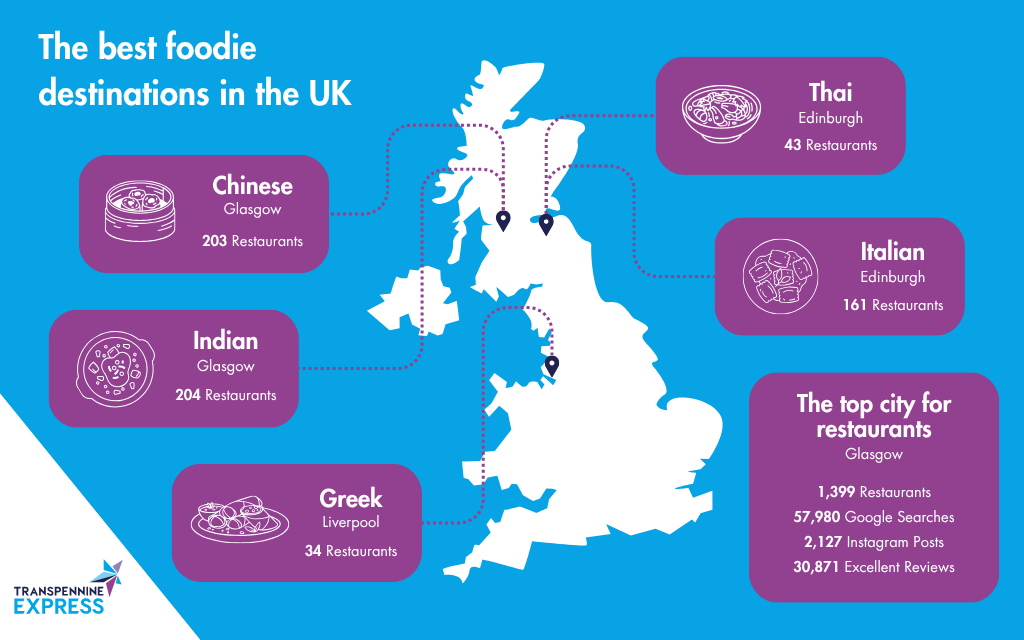

Despite being home to world-class academic research in robotics and artificial intelligence, the UK faces a troubling implementation gap. We currently rank just 24th globally in industrial robot density, lagging significantly behind other G7 nations including France and Italy. As of 2023, the UK had approximately 111 robots per 10,000 employees in the manufacturing sector. This figure is below the global average of 141 and significantly lower than top-performing countries like South Korea (1,000) and Germany (397).

The democratisation of robotics, driven by the rapid rise of Generative AI, means the technology is increasingly within reach for businesses of all sizes — yet adoption rates remain stubbornly low.

The Robotics Revolution in Figures

The numbers paint a compelling picture. Increased robotics adoption could generate £6.4 billion for the UK economy by 2035. Additionally, adopting Industry 4.0 technologies, including robotics, could contribute up to £180 billion to the UK economy over the next decade.

And a recent report by the Food and Drink Federation (FDF) revealed that there is an untapped £14bn ‘productivity opportunity’ for the sector across the UK, which could be unlocked through investments in automation, artificial intelligence and digital technology.

The Scottish Government is alive to the opportunity, committing £321 million to enterprise agencies to support emerging technologies. However, without an appetite to engage with robotics and AI, the opportunity could be lost.

The Readiness Gap

Businesses might cite issues such as cost, uncertainty and the challenge of integrating robotics into their processes as barriers to adoption, but this isn’t simply about spending money and purchasing equipment — it requires strategic planning, workforce training, and operational adjustments.

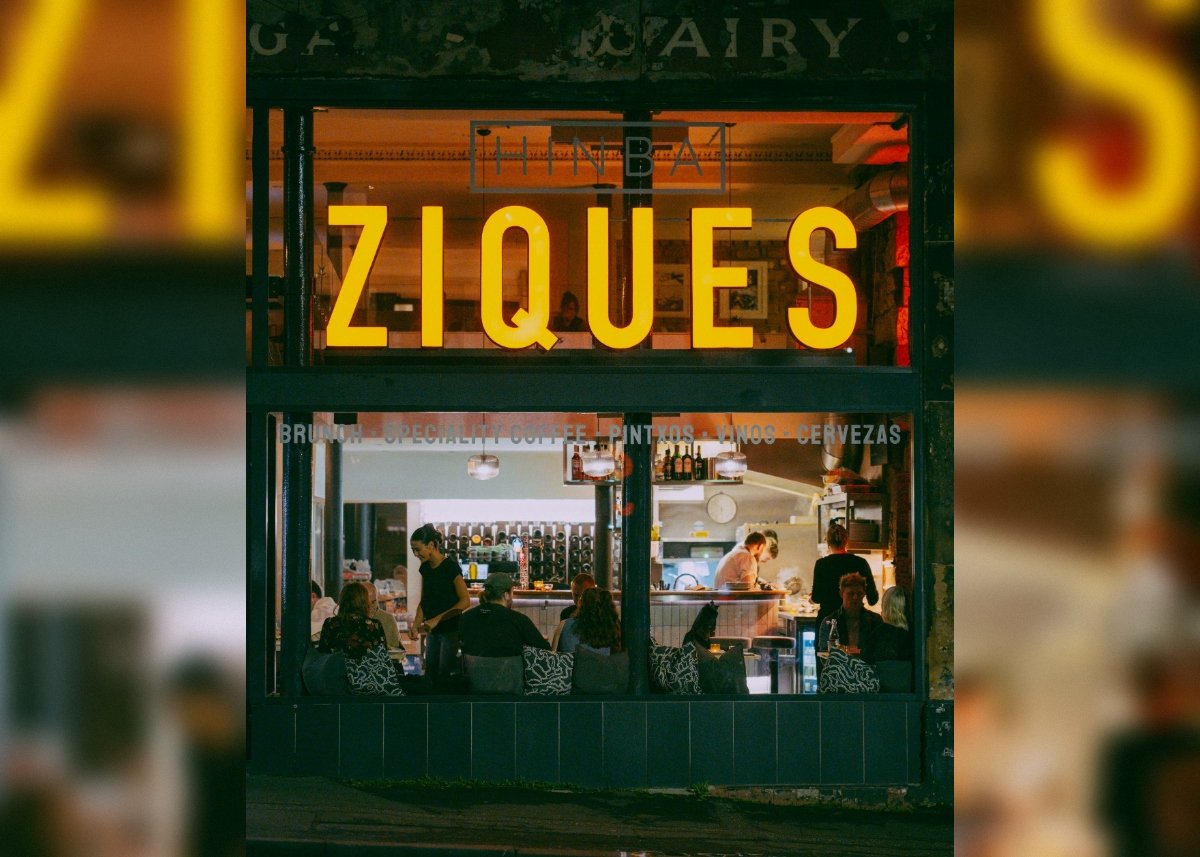

To address this gap, the National Robotarium in Edinburgh, a world-leading centre in robotics and AI, based at Heriot-Watt University, is launching a series of Robotics Readiness Review Workshops. These sessions provide an unbiased, expert-led assessment of an organisation’s readiness for robotic integration. Participants receive bespoke guidance to help them realistically evaluate their current position, understand available technologies, and plan the steps needed for effective implementation.

The workshops, which are free to attend, are designed to demystify robotics and create practical roadmaps for adoption that align with each business’s specific needs and capabilities. By addressing common barriers — from technical knowledge gaps to concerns about return on investment — the aim is to accelerate the responsible integration of robotics across UK engineering.

Case studies: Multinational to SMEs, everyone can benefit

Diageo, Scotland’s largest distiller and the owner of brands including Johnnie Walker, has teamed up with technology giant Siemens, Bellshill-based engineering firm Kigtek, and Strathclyde University’s Advanced Forming Research Centre, to create a filling lance for whisky casks and accompanying software.

The system can fill a 44-gallon cask in less than a minute, with more than 99% consistency. By filling each cask to its maximum level, distillers can cut waste and reduce storage costs by having fewer half-filled casks in their warehouses.

But it’s not just the big companies which can benefit from robotic automation.

Castle MacLellan Foods, based in Kirkcudbright and known for their premium pâtés, introduced collaborative robots (cobots) that work alongside their staff to handle repetitive tasks like placing packed products into boxes and on to pallets. This allowed their skilled employees to focus on the more artisanal aspects of food production where human expertise and judgment add value.

The company took a phased approach to automation, starting with specific bottlenecks in their production line. This strategic implementation of robotics helped them increase production capacity while maintaining product quality and enabled them to meet growing demand without compromising their craft food production values.

Despite facing challenges such as declining sales and market pressures in recent years, Castle MacLellan has maintained its commitment to automation projects, a great example of a company using robotics and automation to enhance their offering whilst simultaneously boosting its bottom line.

Preparing for an Automated Future

The robotics market in the UK is forecast to grow at an annual rate of 4.43% through 2029, potentially reaching a value of almost £215 million. However, these economic benefits will not be evenly distributed. They will flow primarily to those businesses that have prepared strategically for technological adoption.

Scotland’s food and drink sector cannot afford to be passive observers of the robotics revolution. By taking proactive steps toward robotics readiness today, it can position itself to thrive in tomorrow’s increasingly automated industrial landscape.

You Might Also Like:

No related posts.

The future of industry will be shaped by those who embrace these technologies not as threats, but as tools to enhance productivity, sustainability, and competitiveness in global markets.

So, the real question is not whether robotics will be transformational, but whether the country will be ready in time.For more information about the National Robotarium’s Robotics Readiness Review Workshops, please contact Naomi at n.battison@hw.ac.uk or visit the National Robotarium website – https://thenationalrobotarium.com/industry/robotics-readiness/